- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

PVC /WPC profile production line can produce all kinds of profile, for example, window, door and door frame, pallet, cladding of outdoor wall, facility of outside park, floor etc. Output profile is Wood Plastic Composite(WPC) or Plastic UPVC.

WPC Composite Decking Machine/WPC Machine /3D Embossed Decking production line

Product description :

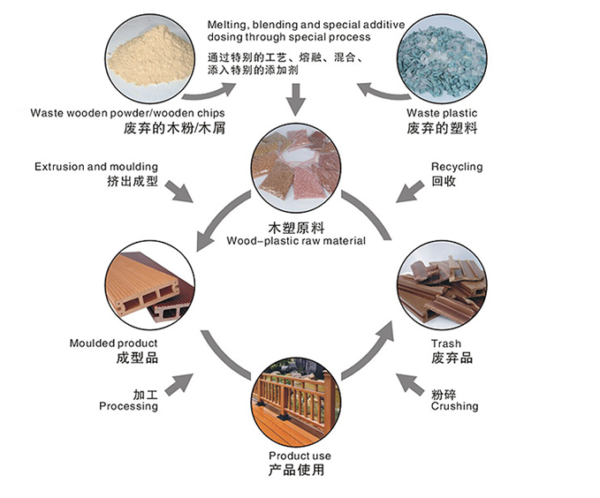

Wood plastic composite is lumber product made from recycled plastic and small wood particles or fibers. Wood plastic composite (WPC) that consists of polyethylene (PE) and wood sawdust tends to be used primarily in building and structural components. Such as decking board, Wall panel, Railing and Fence.

WPC Composite decking boards is made of 30% HDPE (Grade A recycled HDPE),60% Wood or Bamboo powder (Professionally treated dry bamboo or wood fiber), 10% Chemical Additives(Anti-UV agent, Antioxidant, Stabilizes, Colorants, Lubricant etc.)

WPC composite decking not only has real wood texture, but also has longer service life than real wood and requires little maintenance. So, WPC composite decking is a good alternative of other decking.

WPC (abbreviation: wood plastic composite)

Wood plastic composite 3D-embossing decking boards.

Wood plastic composite exterior WPC flooring has been introduced to the market.

The difference from the traditional flooring is the technologically advanced structure. It is a wood-panel system that does not require padding and has a good waterproof function. Wood plastic composite WPC flooring does not require the use of adhesives, it is easy to install through its locking system, which helps to reduce installation time and cost; WPC flooring has sound-absorbing effect, is more comfortable and quiet under the feet, and is very suitable for key environments such as noise reduction.

3D embossing wood grain decking has a wide range of applications. High-quality outdoor composite decking can not only make your home look better, but also serve for a longer life.

It have all the advantages of traditional composite decking ,it is still kept: waterproof, anti-UV, weather resistant, anti-corrosion, anti-termites, temperature resistant, long service life etc…But it looks and feels more like natural wood due to the 3D embossing treatment of the surface.

Wood-plastic composite decking is a new type of environmentally friendly wood-plastic composite material product. Wood phenol produced during the production of medium and high-density fiberboards is added to recycled plastics to make wood-plastic composite materials through granulation equipment, and then extruded into production groups. Made into wood-plastic composite decking.

Technical profile for industry:

1.Conical twin-screw extruder is perfect, with PVC powder or granular material.

2.Mould designed by different kinds of profile customer required.

3.supply formula guide and staple raw material purchase.

Technical parameter of wpc decking machine:

|

Model |

Max width (mm) |

Extruder model |

Max output(kg/h) |

motor power(kw) |

|

CMDX108 |

108 |

SJZ51/105 |

100 |

18.5 |

|

CMDX 180 |

180 |

SJZ51/105 or SJZ55/110 |

100/150 |

18.5/22 |

|

CMDX 240 |

240 |

SJZ65/132 |

250 |

37 |

|

CMDX 300 |

300 |

SJZ65/132 |

250 |

37 |

|

CMDX 400 |

400 |

SJZ80/156 |

350 |

55 |

|

CMDX 500 |

500 |

SJZ80/156 |

350 |

55 |

|

CMDX 600 |

600 |

SJZ80/156 |

400 |

75 |

WPC Decking Production Process

WPC Decking machine Production Process

100% recycled PP,PE,etc+wood power ( from wood dust, rice husk, wheat straw,etc)+ additives → mixing → granulating → conical twin-screw extruder → profile extrusion die → profile moulds→ vacuum calibration platform →(haul-off) → cutter →stacker → finished product → surface finish processing, like embossing, sandng, brushing,etc

Main Composition of wpc decking production line

| Item | Quantity |

| 1.Twin Screw Extruder with Automatic Feeding System | One set |

| 2.Die Mold & Stock Mold | One set |

| 3.Vacuum Calibrarion Table | One set |

| 4.Haul-off Unit | One set |

| 5. Cutter | One set |

| 6.Stacker | One set |

Detail images of wpc decking production machine

1.The all production line of the wpc decking machine

2..Twin Screw Extruder of the wpc decking machine

2..Twin Screw Extruder of the wpc decking machine

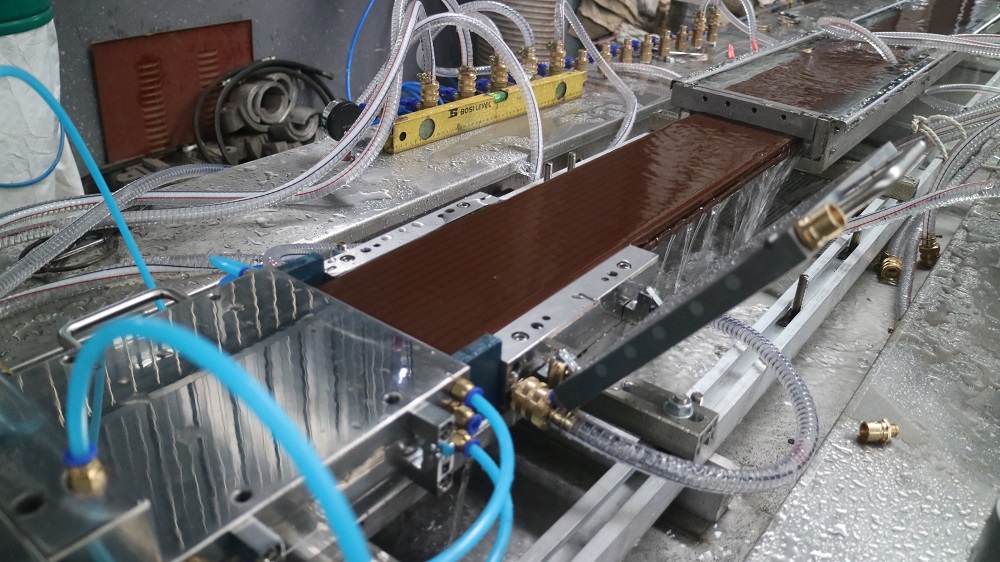

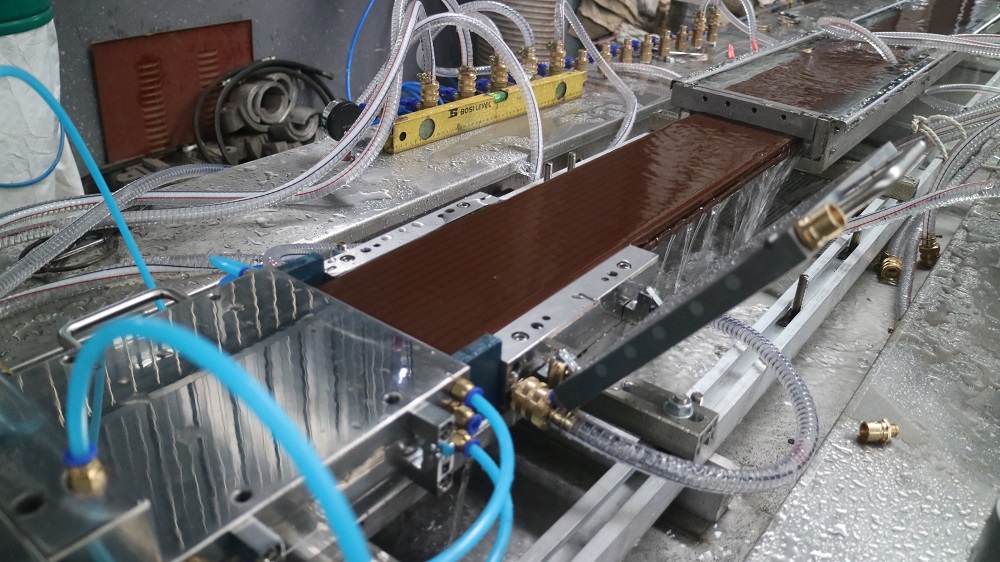

3.Die Mold & Stock Mold of wpc decking machine

4.Vacuum Calibrarion Table of wpc decking machine

5.Haul-off of wpc decking machine

5.Haul-off of wpc decking machine

6.Cutter Unit of wpc decking machine

7.Stacker of wpc decking machine

7.Stacker of wpc decking machine

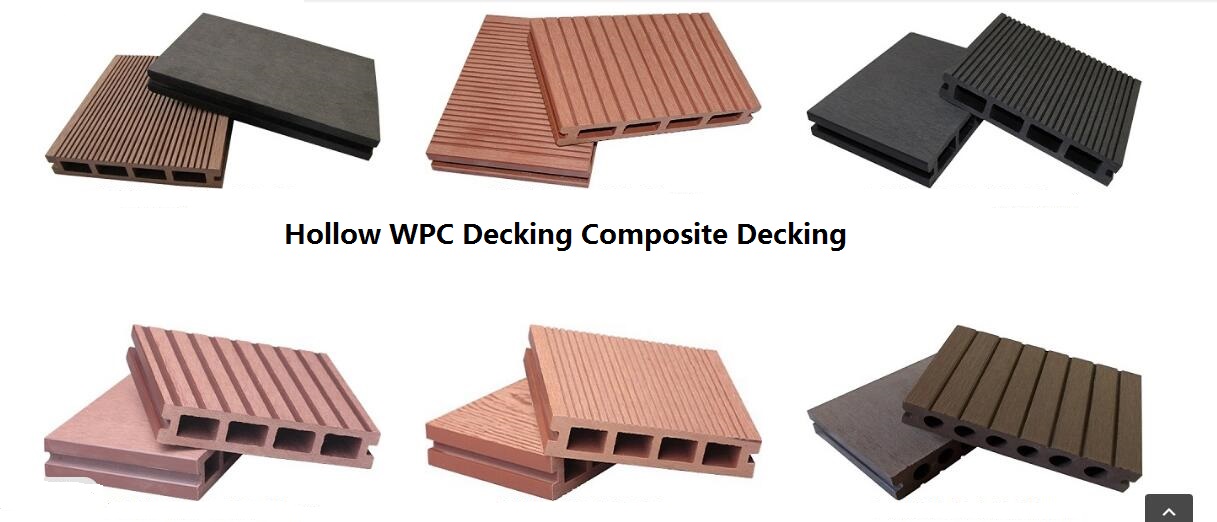

WPC Decking Composite Decking

2.Solid WPC Decking Composite Decking

WPC Decking Used For?

Because WPC decking has following good performance: high pressure resistance, weather resistance, scratch resistance, waterproof, and fireproof, WPC composite decking has long service life compared to other decking. That is why wpc composite decking is wisely used at outdoor environment, such as gardens, patio, parks, seaside, residential housing, gazebo, balcony, and so on.