- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

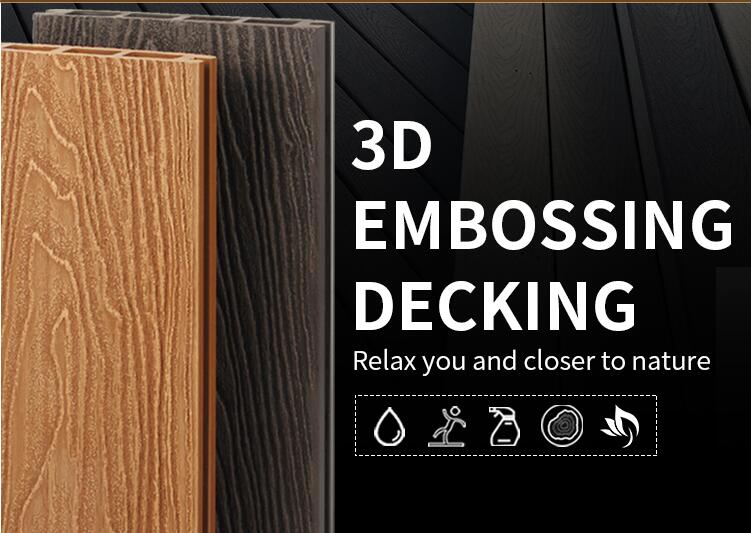

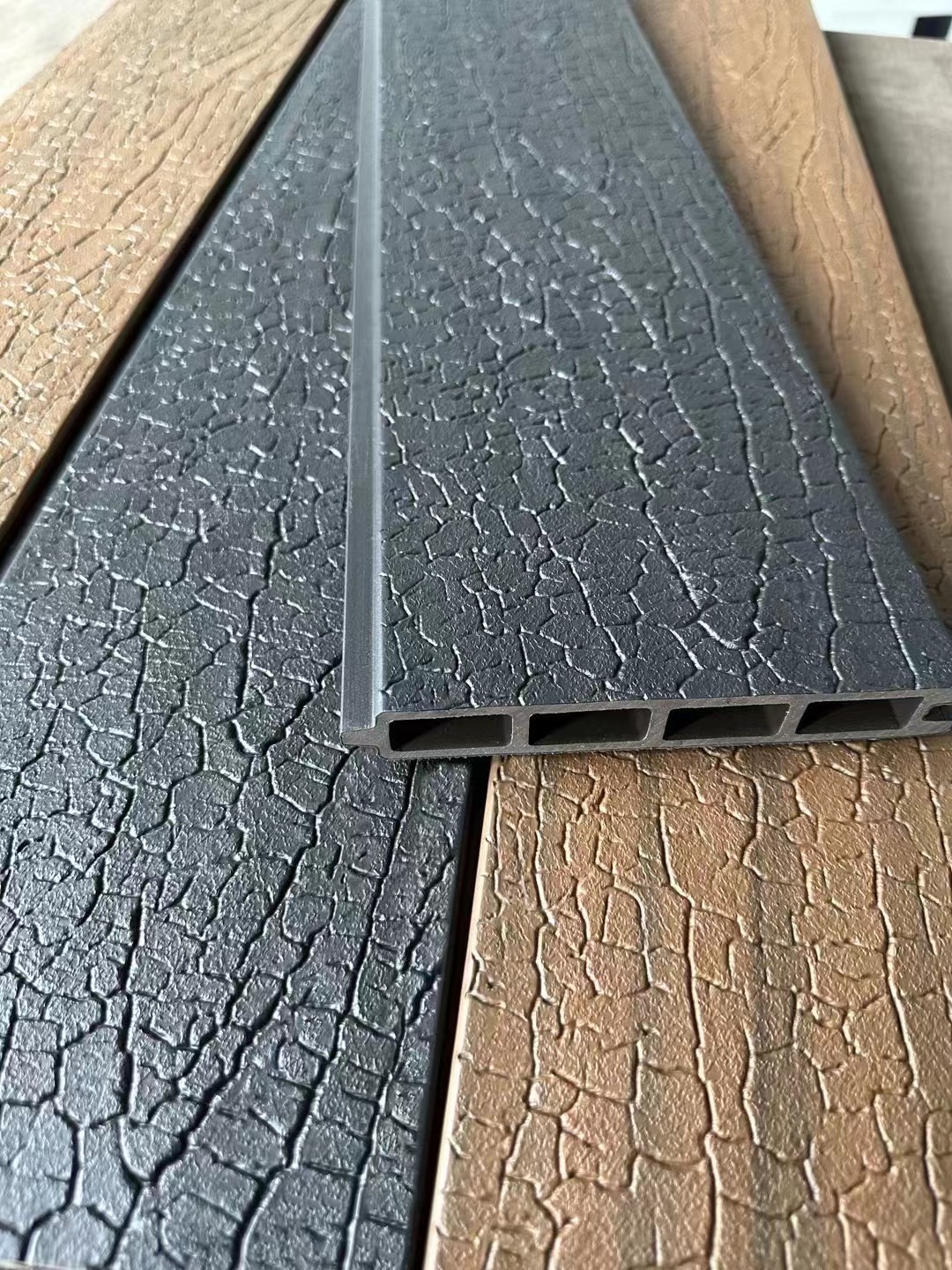

WPC extrusion line with 3D on line embossing machine is used to produce the wood plastic composite profiles with impressive wooden alike patterns for different usage, for example, wpc decking, wpc panel, wpc fence, wpc wall cladding, wpc pergola profile,wpc board,wpc pallet profile, wpc pillar, wpc bench profile, etc.

3D Embossed Decking production line /3D WPC decking production machine

Product description of 3D WPC decking production machine :

WPC extrusion line with 3D on line embossing machine is used to produce the wood plastic composite profiles with impressive wooden alike patterns for different usage, for example, wpc decking, wpc panel, wpc fence, wpc wall cladding, wpc pergola profile,wpc board,wpc pallet profile, wpc pillar, wpc bench profile, etc.

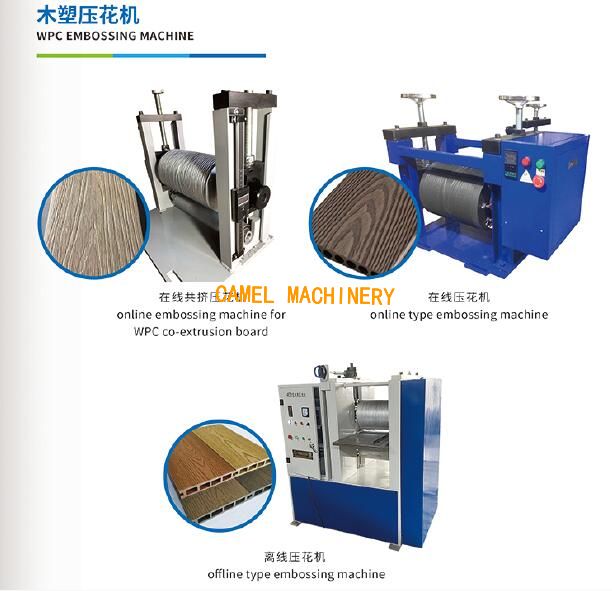

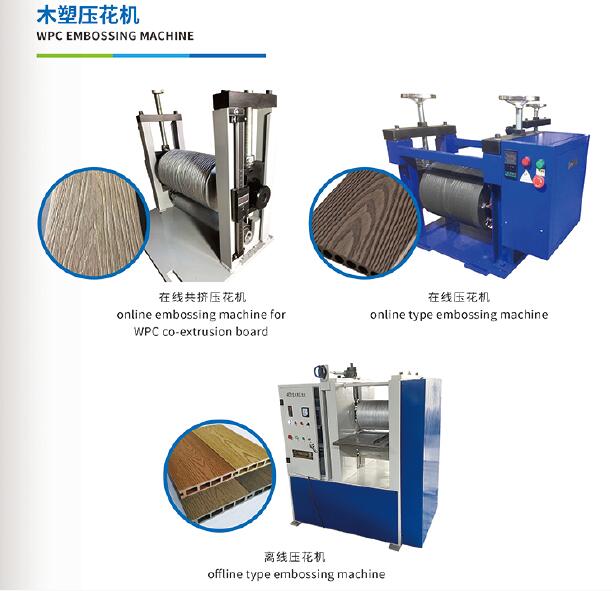

WPC EMBOSSING MACHINE Can make differents kinds grain .

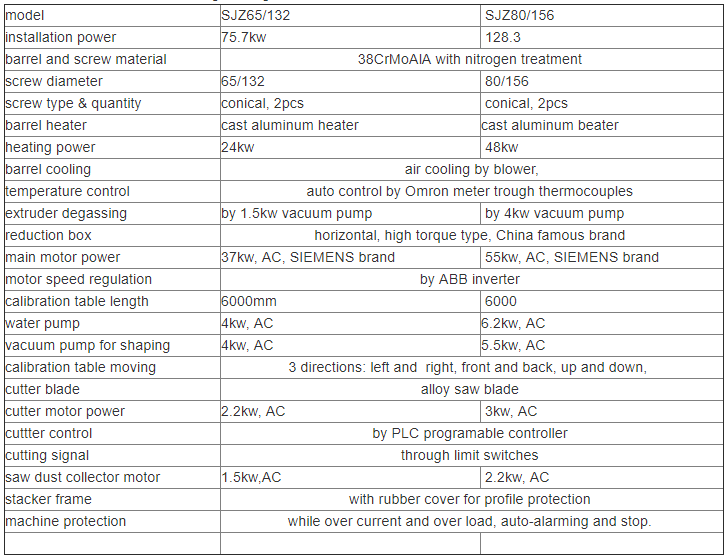

Main Techincal Parameter of 3D Embossed Decking production line

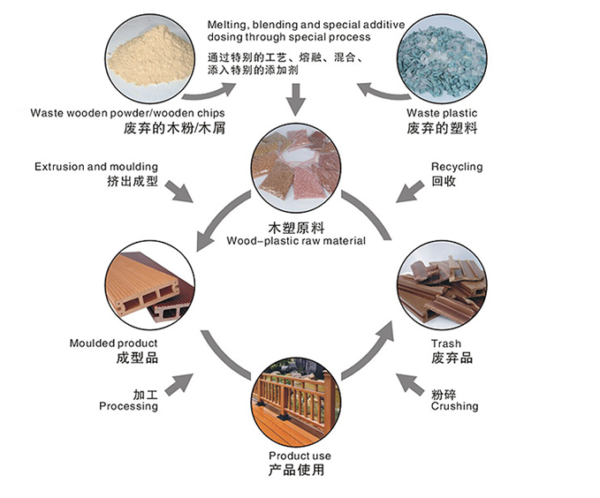

WPC Decking Production Process

WPC Decking machine Production Process

100% recycled PP,PE,etc+wood power ( from wood dust, rice husk, wheat straw,etc)+ additives → mixing → granulating → conical twin-screw extruder → profile extrusion die → profile moulds→ vacuum calibration platform →(haul-off) → cutter →stacker → finished product → surface finish processing, like embossing, sandng, brushing,etc

Main Composition of 3D embossing wpc extrusion line

| Item | Quantity |

| 1.Twin Screw Extruder with Automatic Feeding System | One set |

| 2.Die Mold & Stock Mold | One set |

| 3.3D on line embossing type | One set |

| 4.Vacuum Calibrarion Table | One set |

| 5.Haul-off Unit | One set |

| 6. Cutter | One set |

| 7.Stacker | One set |

For the WPC production, if you can buy the mixed and compounded wpc materials directly, you don't need the wpc mixer and wpc pelletizer.

Beside the wpc machines, we provide full supports on wpc material formula, machine operation, operator training and maintenance guidance.

Detail images of 3D embossing wpc extrusion line

1.The all production line of the wpc decking machine

2.Twin Screw Extruder of the wpc decking machine

Twin screw extruder is usually used for the pe pp wpc production, also for one step extrusion of pvc wpc production.Alloy 38CrMoAlA barrel and screw are assembled on our WPC extruders, with powerful motor and reducer for driving.metering feeder, cast aluminum heater and good vacuum degassing unit.

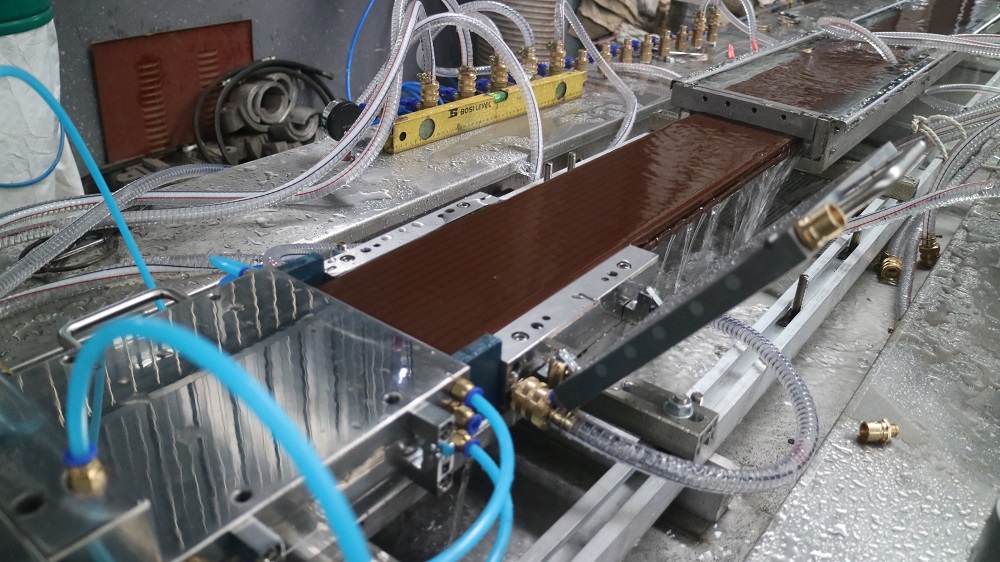

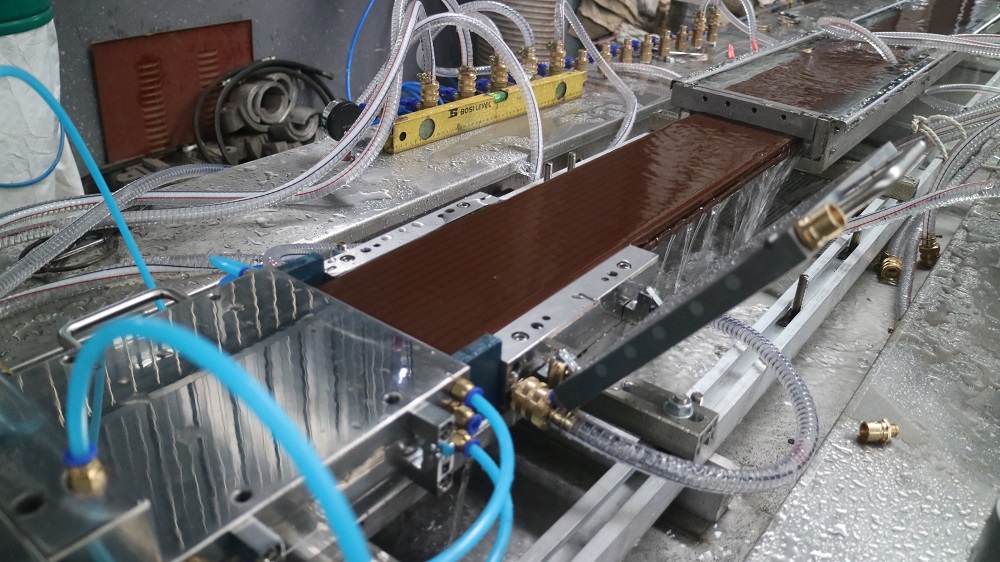

3.Die Mold & Stock Mold of wpc decking machine

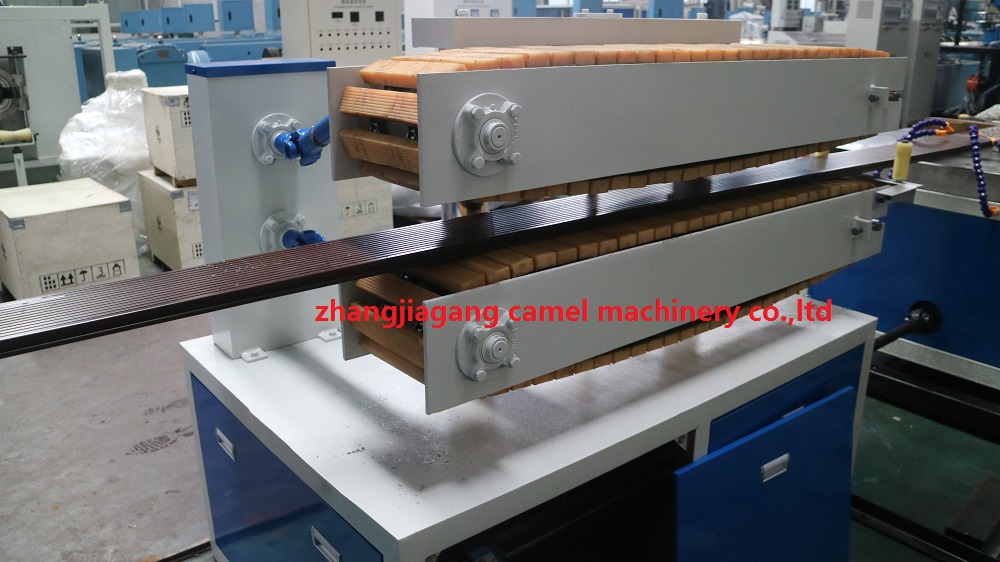

4.3D on line embossing type

5.Vacuum Calibrarion Table of wpc decking machine

Calibration table includes the auto water circular system for cooling wpc profiles, and vortex air dryer for blow off the left water after cooling. It can be adjusted on 6 directions for easy installation and operation of the wpc moulds while production, control panel with waterproof cover, electrical cabinet is hiden in the frame structure, uniform door plates for beatiful apparence.

6.Haul-off of wpc decking machine

The hual-off machine is usually caterpillar type, rubber blocks are used for the belt. Pulling speed is adjustable to meet the different extrusion speed of wpc extruders and shaping speed of wpc moulds.

7.Cutter Unit of wpc decking machine

8.Stacker of wpc decking machine

Advantage of 3D on line embossing WPC extrusion line in CAMEL MACHINERY :

1, beautiful surface making on wpc profiles.

2, alloy for barrel and screw of extruder.

3, accuracy temperature heating and cooling control.

4, steady extrusion with good plasticizing for wpc materials.

5, exquisite processing technics for wpc molds making, fast and good shaping.

6, high automation, labor saved

7, strong structure for the extruder, calibration table, pulling machine, cutter, etc.

8, fix length of wpc profile for cutting automatically and precisely.

9, auto protection function while overload.

10, quality certification.

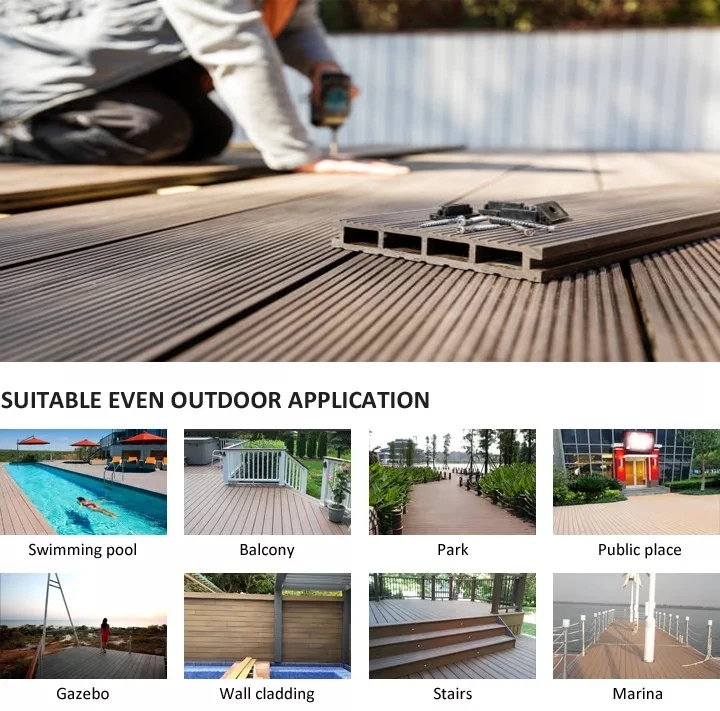

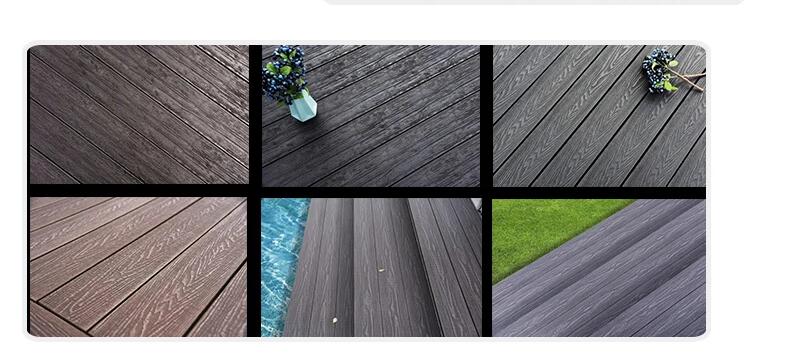

WPC Decking Used For?

Because WPC decking has following good performance: high pressure resistance, weather resistance, scratch resistance, waterproof, and fireproof, WPC composite decking has long service life compared to other decking. That is why wpc composite decking is wisely used at outdoor environment, such as gardens, patio, parks, seaside, residential housing, gazebo, balcony, and so on.