- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

PE Pipe Extrusion Machine is mainly used for producing agricultural irrigation pipes, drainage pipes, gas pipes, water supplying pipes , cable conduit pipes etc. The pipe has some excellent features such as heating resistant, aging resistant, high mechanical strength, environmental stress cracks resistant, good creep resistant, etc. our extrusion line is designed with high efficiency extruder and equipped with reducer which is high speed and low noise, Gravimetric dosing unit and ultrasonic thickness indicator can be assembled according to customer's demand to ascend the precise of the pipes . Turn key solution can be provided, like laser printer crusher, shredder, water chiller, air compressor etc. to achieve high-grade and automatic tube production.

630MM HDPE PIPE MACHINE / HDPE PE pipe extrusion machine

HDPE Pipe Extrusion Machine is mainly used for producing agricultural irrigation pipes, drainage pipes, gas pipes, water supplying pipes , cable conduit pipes etc.

Characteristics: ·

Capacity: single screw extruder, suitable to process PE resin with high capacity, max. 1500kg/h· Diameter: from 16 to 1200mm

Adopts reasonable design, absorbing safe producing technology, acquiring CE & ISO certificate

Flow chart of PE pipe extrusion line:

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder→ color line co-extruder → mould and calibrator → vacuum calibration machine → cooling tank→ haul-off machine → cutting machine → stacker(or winding machine)

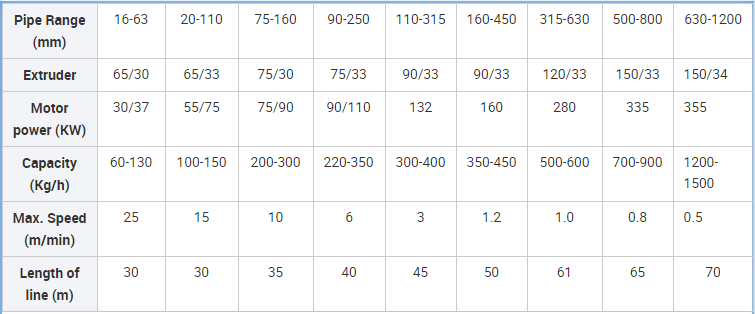

Technical Parameter for PE pipe production machine:

1. Single screw extruder

1. Single screw extruder

--Extruder type: Single screw extruder

--Main motor power(kw): 30/55/75/90/110, etc. Output (kg/h): 80-1500

--Drive motor: Siemens Beide/WEG/WNM brand

--Gear box: Guomao brand, Boneng brand, JC brand, etc.

--European standard electrical components, ABB Inverter, Schneider/Siemens Contactor

--Temperature control: Omron/RKC

--High quality screw and barrel, material 38CrMoAlA, nitriding processing

--With self-protective system, emergency stop button

--Co-extruder: SJ25/25(optional) for color line

--Material feeding, equipped with vacuum feeder and hopper dryer

2. PE pipe die head(Mould)

--Suitable for HDPE pipe production

--Diameter range from Ø16 to Ø1200 mm

--Single layer and multi-layer co-extrusion is optional

--High melt homogenity, and melt channel distribution system

--Low pressure built up even with high outputs

--Equipped with seramic or cast aluminium heaters

--Pipe head carriage for easy movement

--Easy maintenance for the optimized and proven designed construction.

3. Vacuum calibration cooling tank

3. Vacuum calibration cooling tank

--Suitable for PE pipe extrusion

--Pipe diameter range from Ø16 to Ø1200 mm

--Length is customized, such as 6000mm, 9000mm, 12000mm

--304 stainless steel with painted outer surface

--Special water sprays are located on the best position for cooling the pipe efficiently

--Special and easy adjusted pipe supports for each pipe diameter

--Installed vacuum and water pumps can work without any maintenance for long times

4. Water spray cooling tank

--Suitable for HDPE pipe production

--Diameter range from Ø16 to Ø1200 mm

--Length is customized, such as 5000mm, 6000mm, 9000mm, 12000mm

--Material is 304 stainless steel

--Special water sprays are located on the best position for cooling the pipe efficiently

5. Haul-off machine

5. Haul-off machine

--Based on the specification of pipe, 2, 3, 4, 6, 8 and 10 caterpillars are optional

--Enough traction force but not deforming

pipes

--Servo motor driving, or inverter control for providing stable torque and running

--Special designed rubber pads which do

no mark on the pipe

--Synchronic with the extruder speed, allows stable production under different extrusion speed

6. Dust free cutter

6. Dust free cutter

--Frequency inverter control, synchronic with extrusion speed

--Touch screen control panel, Siemens Brand PLC

--Equiped with universal clamp, for PE pipe of various size

--Chip-free cutting, soomth cutting surface without any dust

--High quality dagger knife(material SKD11), extra balde is availble

--Completely closed and secured machine for maximum safety

--It has the advantages of low noise, safe operation, and long service life

7.Final production

Application Description:

---This Pipe Extrusion Line can be used to produce different diameter of PE(HDPE/LDPE), PERT, PP, PPB, PPH, PP-R, IPS pipe.

---HDPE pipe extrusion machine is now in widespread use in many industries particularly industrial piping systems, including underground gas and water pipelines, where it is the dominant material.

---HDPE pipe has excellent stiffness and flexibility, heat resistance, aging resistance, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage, etc. ---Therefore this pipe production line is a preferred for ductwork system of gas, water pipe and agricultural irrigation pipe between city and village.

HDPE municipal water pipe lines is manufactured to provide decades of safe ,and trouble-free operation.With its advantages of high durability and reliability,superior flow characteristic ,and long service life ,HDPE pipe is the cost-effective choice for municipal water application .

HDPE pipe lines can withstand pressure fluctuations and weather changes,resist the corrosive and abrasive effects of the aggressive material that pass through it ,such as aids or salts commonly found in mines and industrial areas .

Usually coiled when manufacturing ,PE100 HDPE agricultural irrigation pipe lines are widely used in gardening and farming applications due to its excellent flexibility ,long service lift and easy connection with drip irrigation system.