- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

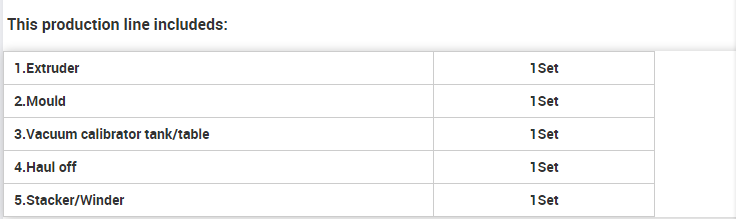

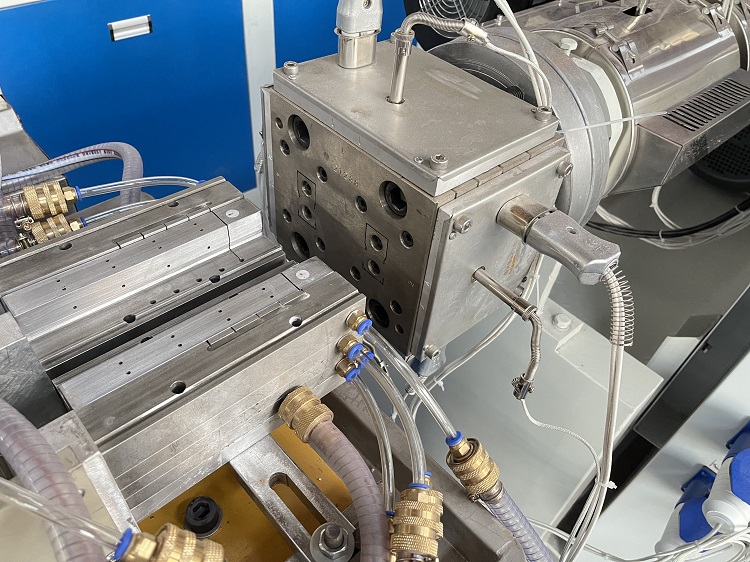

This machine can be used to produce various kinds of belt products including soft/rigid plastic profiles, belt and tube etc. It includes main extruder, precision extruding die and calibration system, haul off unit, cutter, stacker or winder. 1 Capacity: 20-200kgs/hour(It is depending on the product size); 2 Special alloy screw, it adopts imported frequency inverter for extruder and haul off device; 3 Die uses German advanced technique; High quality alloy steel and stainless steel; 4 Molds are customized according to customer samples and drawings, processed by precision CNC equipment; 5 Applicable raw material:PP, PE, PS, ABS, PVC, PA, PTE, PC; 6 Professional technical team provides overseas service, installation, personnel training and technical support.

Production Description :

Application:

This machine can be used in different areas, such as:

1. 3D filament extrusion. (ABS, PLA, HIPS, PE, PP. PA)

2. Pelletizing area.(PE/PP)

3. Small diameter PVC/PA/PC tube extruder.

4. Edge band extruder.(Soft PVC, EVA)

5. Window seal strip.(Soft PVC)

6. Plastic packing strap. (PP, PET)

7. Rattan making.(PE)

8. Photo frame.(PS)

9. Angle skirting.(PVC)

10. LED lamp.(PC)

11. Office Stationery Plastic Profile(PA, PC, PVC, PE)

12. Cable trunking.(PVC)

Machine features

1. Completely european standard, electric protection, heating protection, over load protection.

2. All electric parts are all internationally famous brand.

3. Machine size can be designed based on customer demands.

4. The electric control box can be replaced by PLC control.

This machine can be used to produce various kinds of belt products including soft/rigid plastic profiles, belt and tube etc. It includes main extruder, precision extruding die and calibration system, haul off unit, cutter, stacker or winder.

1 Capacity: 20-200kgs/hour(It is depending on the product size);

2 Special alloy screw, it adopts imported frequency inverter for extruder and haul off device;

3 Die uses German advanced technique; High quality alloy steel and stainless steel;

4 Molds are customized according to customer samples and drawings, processed by precision CNC equipment;

5 Applicable raw material:PP, PE, PS, ABS, PVC, PA, PTE, PC;

6 Professional technical team provides overseas service, installation, personnel training and technical support.

Detail Images :

Single Screw Extruder

Motor Brand: SIEMENS Gearbox: Guomao Electric parts: SIEMENS or OMRON

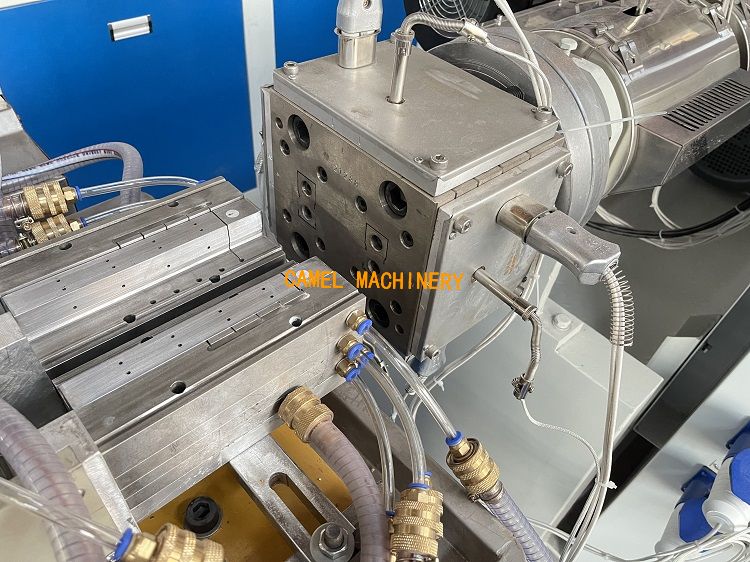

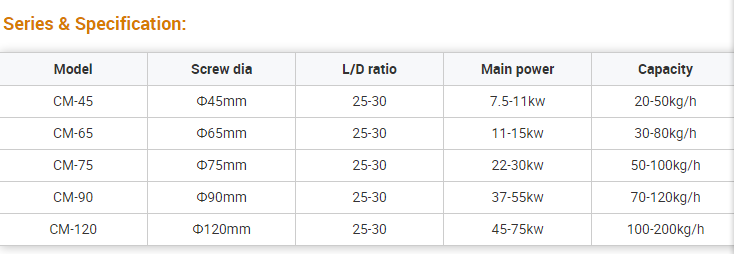

Die Head+ Forming Mold

Molds are customized according to customer samples and drawings, processed by precision CNC equipment

Mold Materials: High quality alloy steel and stainless steel

Forming Table/Tank

Precise control, reasonable design, easy operation

Table materials: Stainless steel