- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

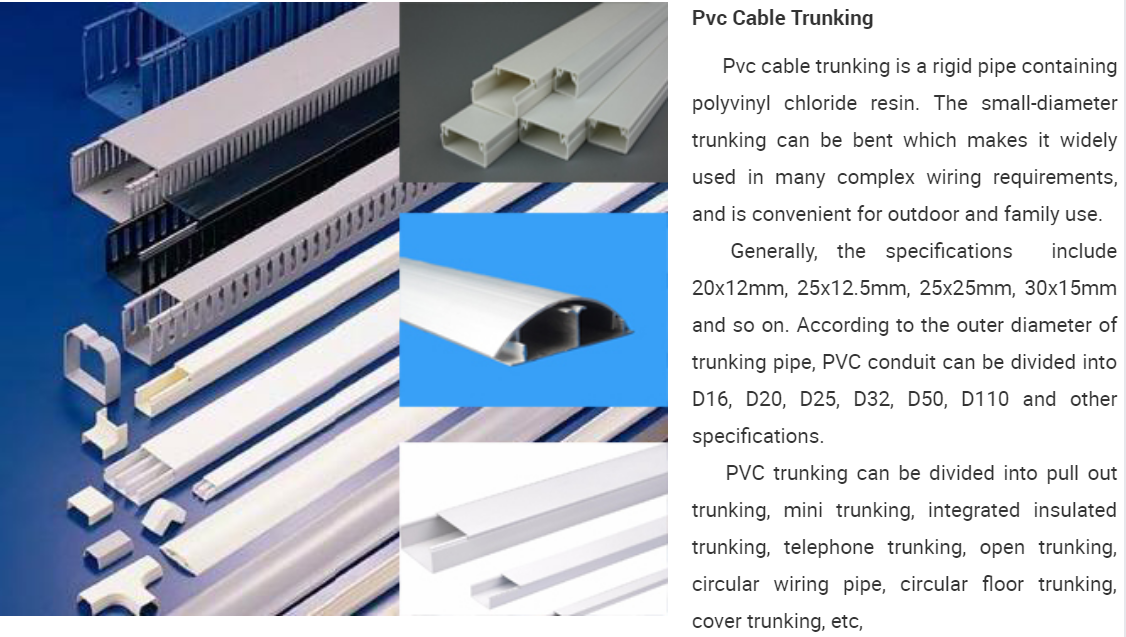

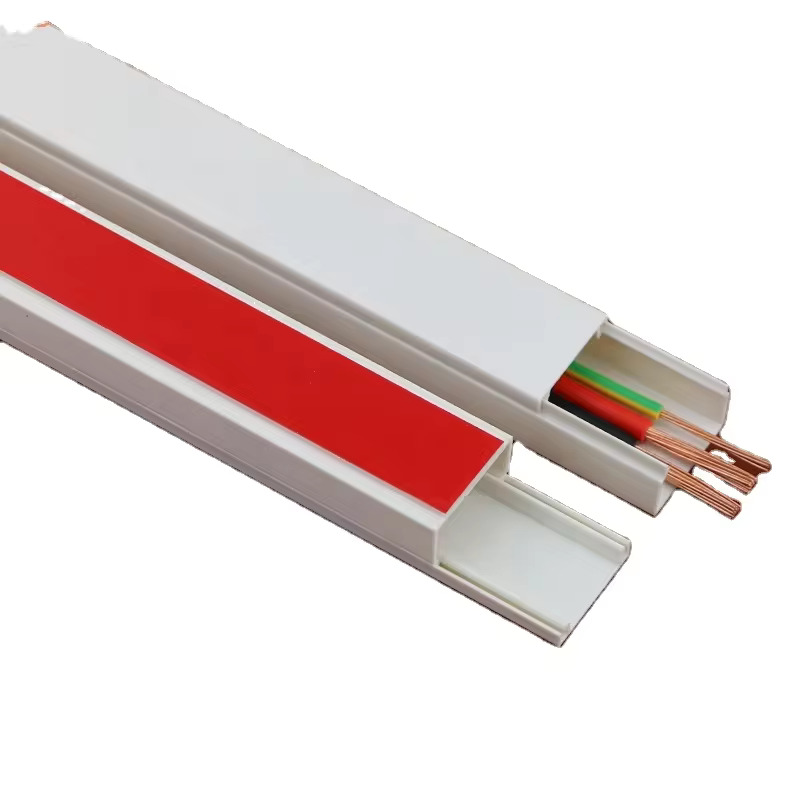

PVC Profile Machine Plastic Electric Cable Wiring Duct Canal Trunking Making Machinery is suitable for producing all kinds PVC wire trunks in all sizes. It is widely used to produce the PVC electric conduit pipe wire and cable pipe, wire trunks and all kinds of profiles. It is the ideal system for unobtrusive cable management designed to cope with the rigours of the factory and office.

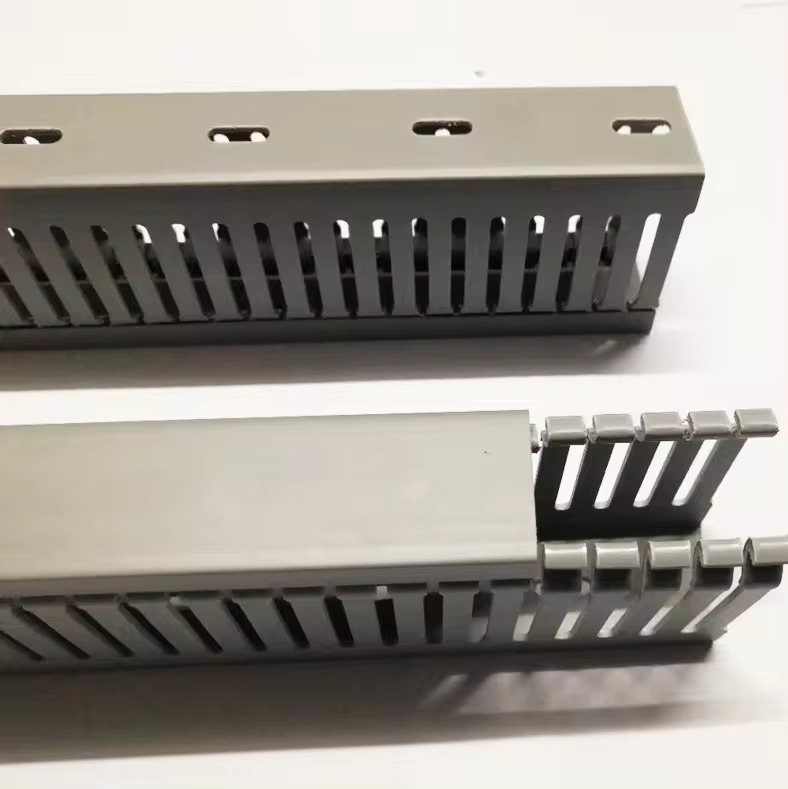

PVC Slotted Cable Duct is designed to provide superior ducting while simplifying your cable management. Featuring parallel holes along the sidewalls to offer easy cutting in wire installation. Whether you use this electrical cable duct for power distribution, control, and communication, our PVC slotted cable duct effectively conceals them.

cable ducts are very light and are appropriate in environments where multiple small cables are likely to be installed and the number of wires increased or decreased. In addition, they offer flexibility to meet your changing needs during the process of concealing open wiring systems – simply lay the cables in the tray rather than pulling through a pipe.

PVC slotted cable duct making them an excellent investment for your construction projects.

Available Colours

* White

* Grey

Areas of Application:

Skirting, Main Circuit, Computer Wiring Switch Board / Panel, Sheathed Cable Wiring, Telephone & Intercom Wiring, Air-Conditioner / Chiller Plant Installation etc.

PVC cable trunking extrusion line

2.Extrusion mould

5. Cutting machine

5. Cutting machine