- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

These plastic pulverizer machines are high speed, precision grinders for the processing of medium hard, impact resistant and friable materials. The material to be pulverized is introduced through the centre of a vertically fixed grinding disc which is mounted concentrically with an identical high speed rotating disc. Centrifugal force carries the material through the grinding area and the resulting powder is collected with a blower and cyclone system. Depending on the application the machines can be equipped with one piece grinding discs or grinding segments.

PE PVC Scraps Plastic Recycling grinder Pulverizer mill machine

These plastic pulverizer machines are high speed, precision grinders for the processing of medium hard, impact resistant and friable materials. The material to be pulverized is introduced through the centre of a vertically fixed grinding disc which is mounted concentrically with an identical high speed rotating disc. Centrifugal force carries the material through the grinding area and the resulting powder is collected with a blower and cyclone system. Depending on the application the machines can be equipped with one piece grinding discs or grinding segments.

The plastic pulverizer machine is mainly composed of electric motor, disc type blade, feeding fan, vibrating sieve, dust removing system, etc.

According to the customer's needs, you can choose some accessories, such as converter, vacuum loader, screw loader, magnetic net, metal separator, chiller, pulse dust collector, metering and weighing packaging machine, etc.

Details of pulverizer:

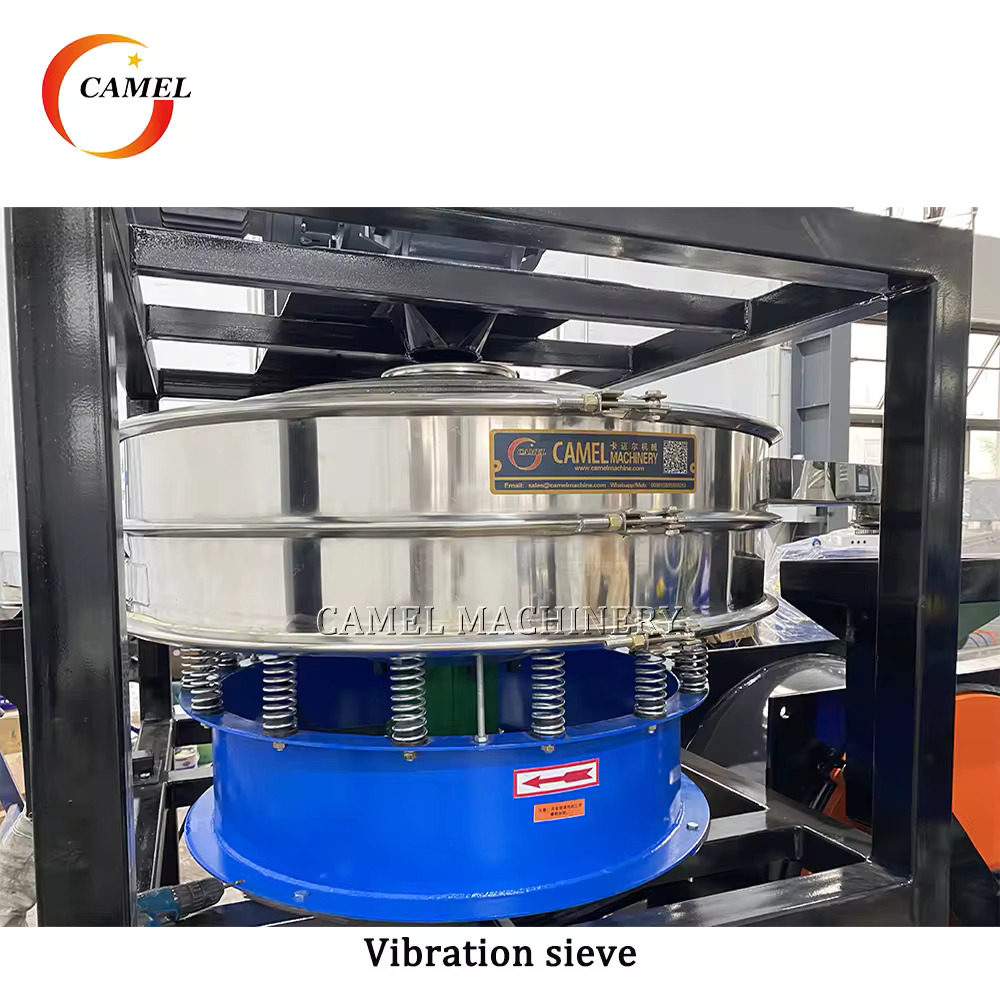

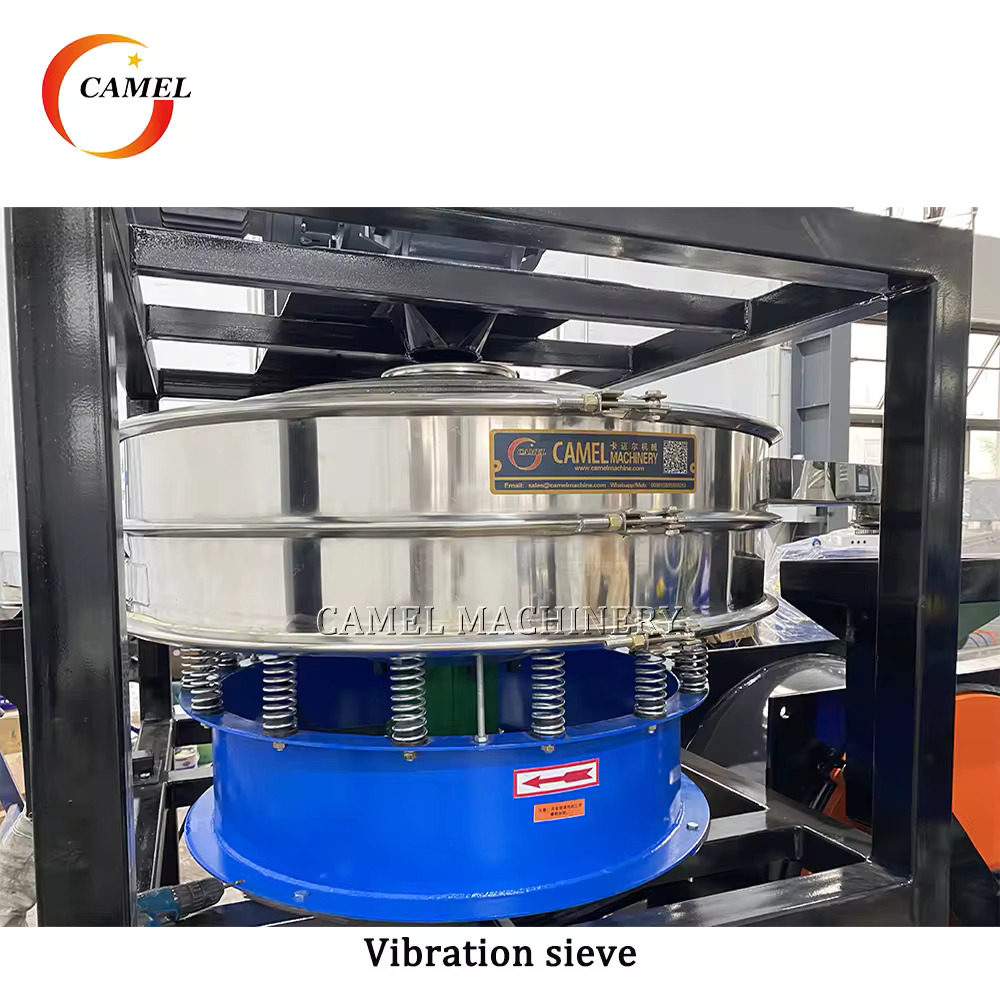

Vibration sieve of plastic pulverizer

Made of stainless steel Use the latest design to expand the filtration area and increase output Filter mesh can be according to customer requirements

Made of stainless steel Use the latest design to expand the filtration area and increase output Filter mesh can be according to customer requirements

Milling chamber and bearing

Use of imported bearings Double layer chamber design, Cooling by circulating water.

Use of imported bearings Double layer chamber design, Cooling by circulating water.

Control cabinet

All kind of electric parts is Siemens and Schneider. With ABB or Delta inverter, including emergency stop device. Support customization.

Highlight:

Magnetic device

Dust remover of pulse

For dust collection system, you can choose a fabric bags dust remover or a pulse dust remover to protect the environment of your workshop.

General description:

Main features of PE LDPE LLDPE pulverizer(Disc type):

1.Low power consumption, high capacity

2.Simple structure and easy installation.

3.Host with the wind ,water circulation cooling system.

4.This Plastic pulverizer can deal with PE, LLDPE, LDPE, ABS, EVA, PET, PP etc.

Technical data:

| Model | MP-400 | MP-500 | MP-600 | MP-800 | MP-1000 |

| Diameter of milling chamber(mm) | 350 | 500 | 600 | 800 | 1000 |

| Motor power(kw) | 22-30 | 37-45 | 55 | 75/90 | 90/110 |

| Cooling | Water cooling + natural cooling | ||||

| Air Blower power(kw) | 3 | 4 | 5.5 | 7.5 | 11 |

| Fineness of power | 10 to 100 mesh (Can be adjustable) | ||||

|

Output of pulverizer

(kg/h)

|

80-150 | 150-250 | 200-400 | 300-500 | 500-800 |

| Dimension (mm) |

1800×1600

×3800

|

1900×1700

×3900

|

1900×1500

×3000

|

2300×1900

×4100

|

2500×2300 ×4100 |

| Weight (kg) | 1300 | 1600 | 1500 | 3200 | 3600 |

Main features of PVC pulverizer(Rotor type):

1. The capacity of this model is higher than other kind of miller. 2. Equipped with dust collection device to reduce dust pollution. 3. Close blower for discharge can reduce labor intensity of worker and save money for clients. 4.The cover of main machine can be opened for maintain. 5.The cooling system include the water and wind cooling for the machine body.

Technical data:

| Model | SMF-400 | SMF-500 | SMF-600 | SMF-800 | SMF-1000 |

| Main Motor power (kw) | 30 | 37 | 45/55 | 55/75 | 90/110 |

|

Capacity (kg/h) |

50-120 | 150-200 | 200-400 | 400-600 | 600-800 |

| Material of conveying pipe | |||||

|

Weight of PVC pulverizer (kg) |

1000 | 1200 | 1800 | 2300 | 3200 |

| Cooling | Wind cooling +water cooling | ||||

Company Information

Certificate

Our supplier